Once the sills were completed, things have moved on apace (due to lots of spare time in COVID-19 Lockdown). I made the decision that the next phase will be to strip down to the chassis, treat that, then rebuild literally from the ground up - it's not good having a rebuilt engine sitting around not being used and I don't want a newly restored body getting scratched during other work, so that's the plan. Before stating the body separation, there was a little rust hole on the rear inner wing /boot just above the wheel. Although the major body repair will be a later stage, I may as well do this as it is accessible and my welding gear is at hand. Of course the rust pin hole turned into a much bigger hole but I made up a repair panel and welded it in. I had visions of renovating the petrol tank once it was off, but all hope of that vanished once I saw the underside.

Click thumbnail

The body is held onto the chassis by just 31 bolts. Most are fairly accessible and were unscrewed after a soaking with PlusGas. It was only the two pairs of bolts holding the duct panel to the chassis extension at the very front of the vehicle that had the heads removed by a cutting disc. The real problem was at the very back of the vehicle, inside the boot, where there are two pairs of bolts behind the rear valance. The penultimate bolts wouldn't budge but was able to get good grip and they eventually sheared off. The two at the very rear were a bit more problematic - I wasn't able to get good purchase on the bolt head in the boot and the head soon rounded off. Finally I made up a brace that was welded onto the bolt head to give sufficient torque to shear one bolt whilst the other actually unscrewed.

With all bolts removed (including the two behind the B Pillar accessed from underneath that many folk forget) I was able to lift the rear, then the front, by a couple of inches and my wife inserted some 2x2 wood across the width of the body for it to rest on - these would act a handles later for the big lift. I was able to check to ensure nothing further was attached - the steering column would stay in place, for now as the UJ wasn't playing ball. Then, with the help of three friends, we lifted the body straight off using the wooden poles and placed it on a wooden stand for now - it was literally a five minute job and 2m social distancing (COVID-19 precautions) was maintained throughout.

Click thumbnail

With chassis fully exposed, I was pleasantly surprised with the condition of the metalwork. The floorboard rails are usual candidates for rust disintergration but, apart from two sections, it appears to be servisable. The battery cradle is a mess, but I knew that anyway. Hopefully, it may just be a case of getting down and dirty to clean, prep, and paint the chassis (that may come back to bite me).

Click thumbnail

The rear axle came off with all bar one bolt (left spring eye bush) coming out after only gentle persuasion. A grinder and reciprocating saw made short work of the troublesome bolt that was corroded solid in the steel sleeve, and the axle assembly was free. The shock absorbers are shot but the axle and leaf springs seem in good condition.

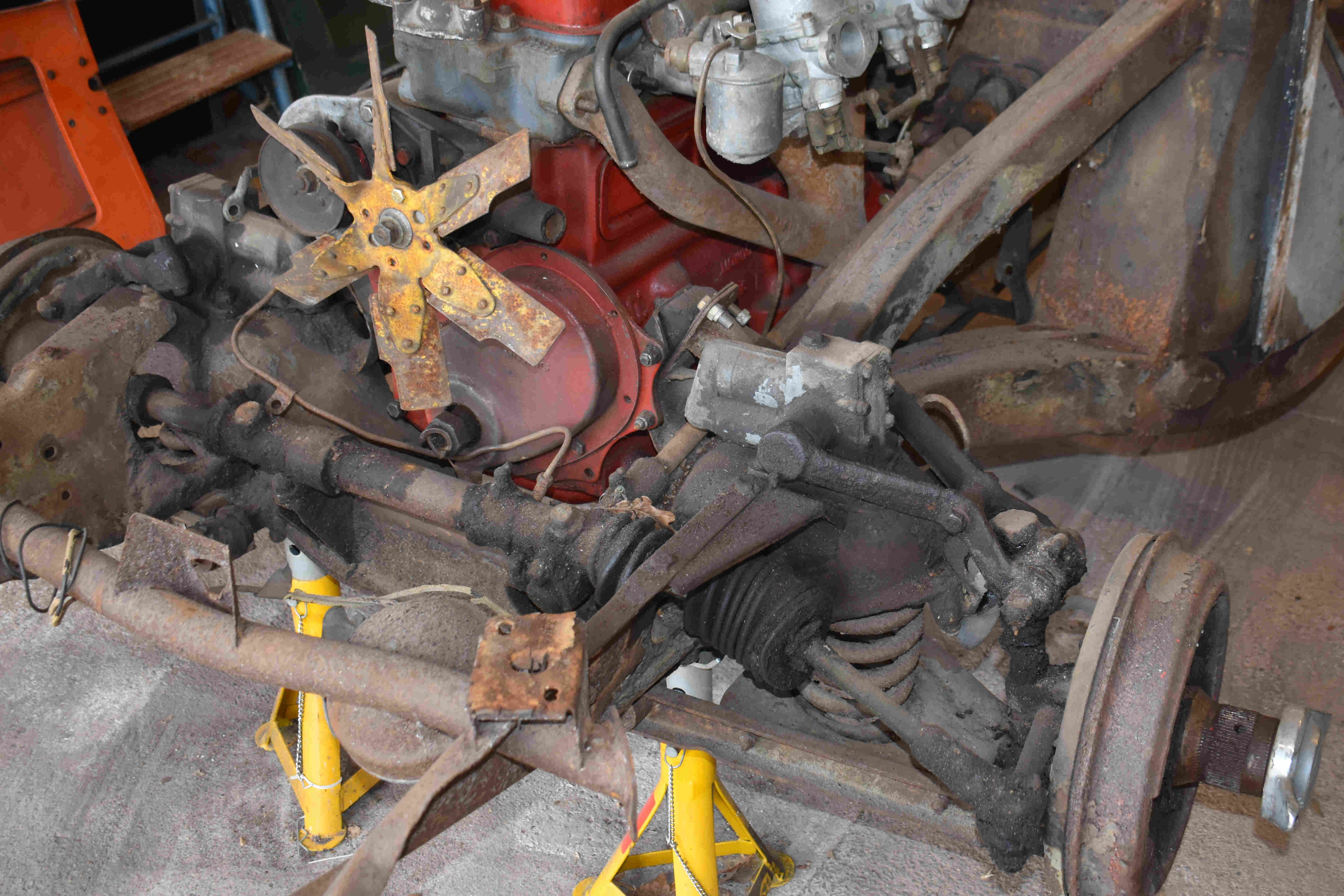

The front suspension was bit more daunting, but I was pleasantly surpised. A couple of bolts were ground off on the chassis extension (which will be replaced) but the rest of the nuts and bolts came free with a quick squirt of GasPlus. The trunnion bolts slid out with reassuring ease as they were still well greased. There didn't appear to be any play in the wheel bearings or the king pins so it looks good for just a clean up and replace the rubber bushes. Even the brake shoes were in good order (although they will be replaced as a matter of course), the coil springs were in spec, and the shock absorbers were giving good resistance. The only problem area was the steering column whose universal joint was totally seized so had to be ground off - this will be replaced by a new RHD steering rack.

Click thumbnail

(Update 30/4/2020) The engine lifted out quite easily, especially as a few bolts were missing. I know nothing of the history of the engine but the head appears to be new / reconditioned, so I'm hoping the rest of it has also. More of that to come later.

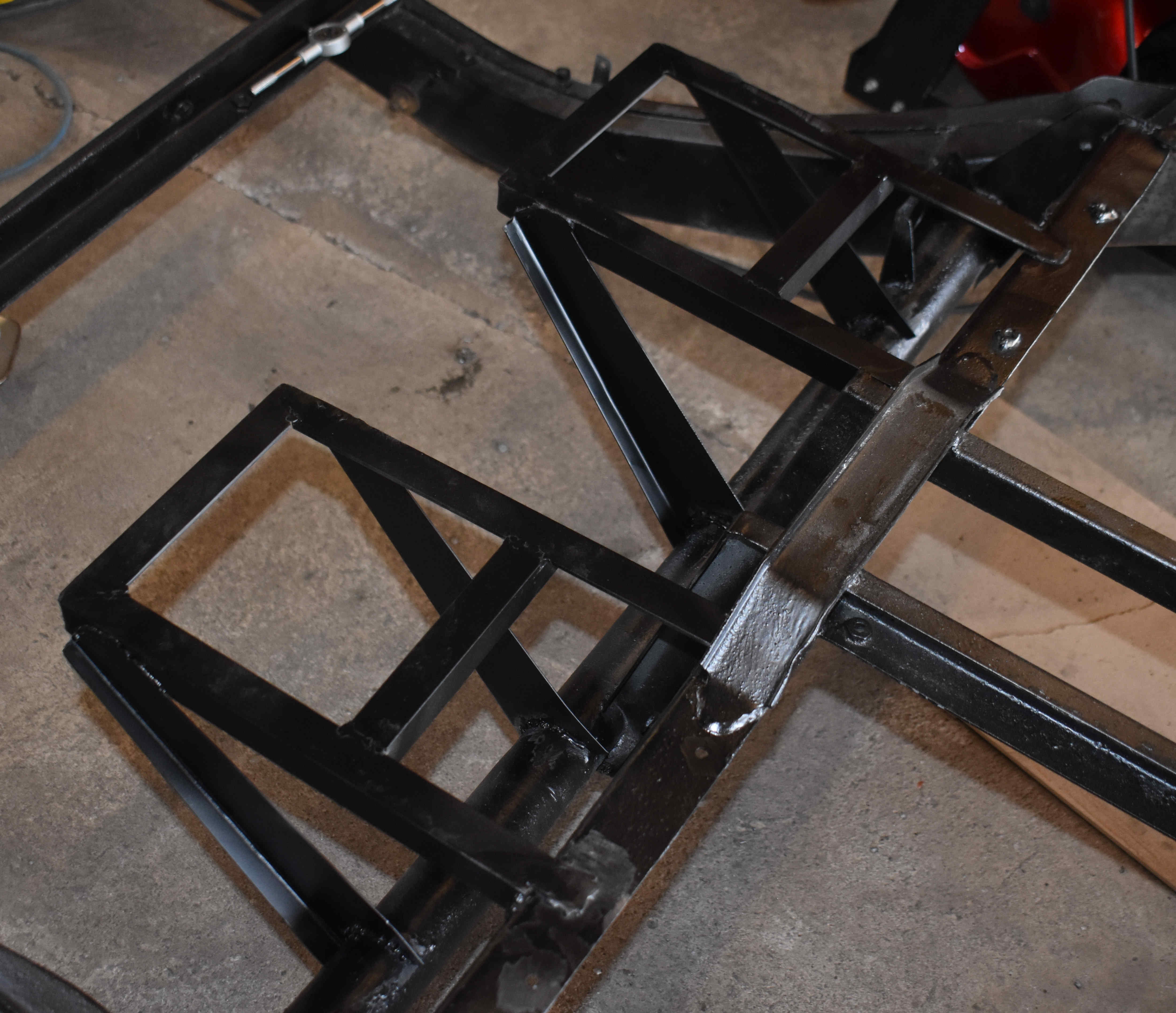

Apart from a bit of surface rust, the chassis appears in good fettle. Two replacement floorboard rails at the front and another for the lefthand side were made up out of 2mm sheet and welded in. Someone in the past had, presumably, replaced the floorboards but could not find the correct 1/4" UNC bolts so (anoyingly) drilled out the captive nuts to 6mm and affixed the boards with a nut on the underside - these have been ground out and the correct size welded in. New battery cradles are available, but at a price, so I made up a couple using 3mm angle iron - that's thicker steel than the originals but it only cost £10 in material (a tenth of the replacement cost) and won't rot quite as quickly.

Click thumbnail

The chassis surface rust was rubbed down and a liberal coat of Eastwood Platinum Rust Encapsulator applied prior to spraying with Chassis Black to all surfaces. The car was manufactured before the days of compulsory seat belts so does not have any fittings for such. Although not a legal requirement, as the chassis is stripped down to this level, some 7/16" fixings were welded in place - I'll work out how to fit the inertia reels later during the body build.

Click thumbnail

That's it for the chassis. Now comes the fun part - bolting the (refurbished) suspension stuff back on which is the start of the rebuild.