Initially I was concerned that an early compression test showed equal pressures in 1, 2 & 3 but was a bit down on 4. After fitting the radiator and running the engine up to normal temperature, with oil circulating properly, another compression test showed all four cylinders roughly equal at just over 100 psi - what a relief!

Although they were all there, the floorboards were is a bit of a state with some screw holes having been ripped out and the rear ramp board (separates the cabin from battery compartment) broken in two. Replacement kits are available but, just for cut plywood, do not come cheap. The original boards were 3/8" ply but I decided to use 1/2" hardwoood external grade to give a little extra strength and insulation (noise & heat). Using the original boards as templates all seven pieces were cut from a single 8' x 4' sheet with plenty left over to replace the seat bases when that time comes. More fettling was required than expected as the previous boards were replacements, but not that accurately cut. Also the thicker board meant further trimming around joins and handbrake / seat belt mounts. Once a good fit was achieved, they were given two coats of Cuprinol wood preserver from Glendale Paints then another two coats of Blackfriar Satin Black Paint. Before final fitment, all mating surfaces were sealed with self adhesive 25mm wide 4.5mm thick closed cell foam tape - hopefully this will make a water tight seal all round.

Click thumbnail

A previous owner had decided to fit a smaller 15" steering wheel - I may need to do this later depending how much room there is for my long legs. Instead of using the proper boss to fit the wheel, another boss was butchered and fitted onto the end of the adjustable steering column by welding a steel pipe fitting & cutting the column extension. That effectively ruined the end of the column, and replacements are difficult to find and exorbitantly expensive. Eventually I was able to source a complete secondhand adjustable steering column which has cleaned up quite nicely with replacement bushes. (Note: MGAGuru makes a big issue about fitting new felt bushes and having to shave them down to fit. The MGOC supplied felt bushes were exactly the correct size so fitted perfectly without any fettling)

A previous owner had decided to fit a smaller 15" steering wheel - I may need to do this later depending how much room there is for my long legs. Instead of using the proper boss to fit the wheel, another boss was butchered and fitted onto the end of the adjustable steering column by welding a steel pipe fitting & cutting the column extension. That effectively ruined the end of the column, and replacements are difficult to find and exorbitantly expensive. Eventually I was able to source a complete secondhand adjustable steering column which has cleaned up quite nicely with replacement bushes. (Note: MGAGuru makes a big issue about fitting new felt bushes and having to shave them down to fit. The MGOC supplied felt bushes were exactly the correct size so fitted perfectly without any fettling)

A secondhand steering wheel was sourced but this suffered from the usual bakelite cracking where the splines meet the rim. An attempt to repair this with epoxy resin coloured with deactivated charcoal was made which did a half decent job, but still visible. The rim was sound, but not pretty, so it will be covered with a nice leather cover which will not only look good, but will feel nice too.

As expected, the Master Cylinder was totally seized so I followed Chad Pagel's tutorial whereby you pump grease from a grease gun into the outlet at pressure which pushes the piston out - seems far fetched but it worked a treat. The rest was a massive clean-up and replacement of all the seals after honing the bores.

Click thumbnail

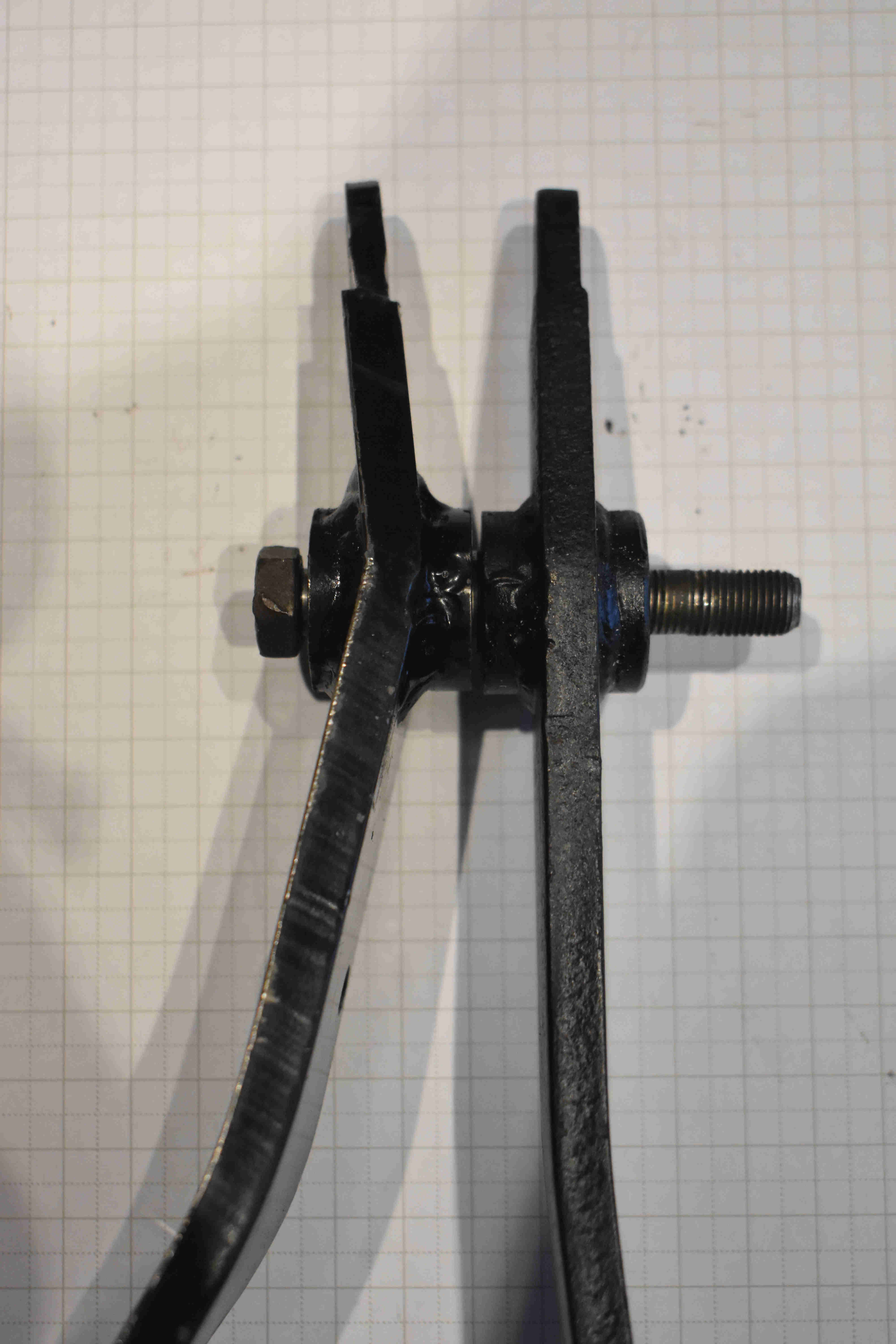

The clutch pedal was missing from the box of bits, but this is one of the items that need to be replaced when converting from LHD - the RHD version has a dog leg to bend around the steering column, not present on the LHD version. After searching long and hard for a used part, I resorted to buying a new patterned one from NTG (other suppliers use the same supplier). Someone is knocking these out and it was a bit rough and ready but, hey, it not on show but should do the job. It soon became clear that the new part was longer than the brake pedal - it transpires that the pedals were elongated during November 1958 at chassis No. 58713 (but RHD clutch didn't change until 61100) where the pedals were extended from 13" to 14", as follows:-

| Brake (RHD & LHD): | AHH5090 --> AHH5840 |

| Clutch (RHD): | AHH5091 --> AHH5841 |

| Clutch (LHD): | AHH5117 --> AHH5842 |

Click thumbnail

I have also been playing around with the Jaeger instruments. The fuel gauge didn't work but I have sourced a used but working Jaeger one to replace. The oil/water gauge was ruined by someone cutting the water capillary pipe, but I managed to get a working Smiths gauage and will swap the faces later. The speedo and tacho appear to work so will need a good clean up. All this will be done at a later date.

Now on to the bodywork!