I knew nothing about the history of this engine but, on first impressions, it appears to have been rebuilt but not completed or run. From first looks there are a number of bolts that are missing as well as a number of components that were in a box (crankshaft pulley, fan pulley) rather than on the engine. Closer inspection revealed the crankshaft pulley rivets are excessively loose (presumably why it was in the box) and there is no oil seal on the timing cover. A big giveaway was that (when I clouted it with a spanner) the sump rang like a bell so was completely dry. At least it turns by hand (no starter motor so can not test compressions).

On the positive side, the cylinder head looks either brand new or reconditioned as it is unpainted and in pristine condition. One would hope that if someone went to the trouble of renewing the cylinder head, they would have rebuilt the bottom below it. Time would tell.Off came the cylinder head and the bores looked remarkably good - no sign of scoring and only a very slight (almost undetectable) lip at the top. It has obviously been rebored sometime in the past but no clue as to when. The bottom looked good as well with a brand new oil pump in place. As far as the eye can tell, it looks good to go so it was cleaned up, given a coat of MG Maroon engine lacquer, then reassembled with new gaskets and seals.

Click thumbnail

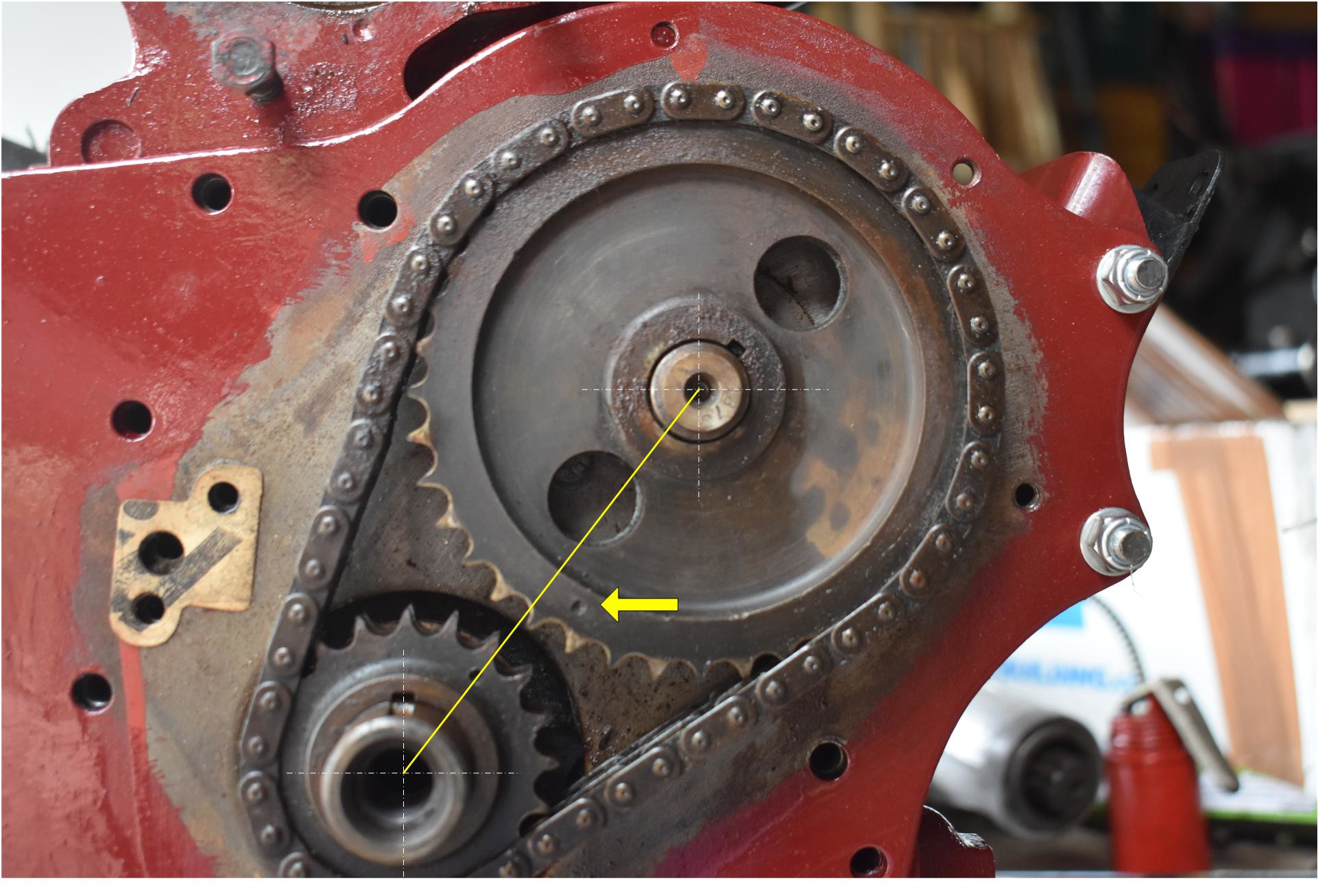

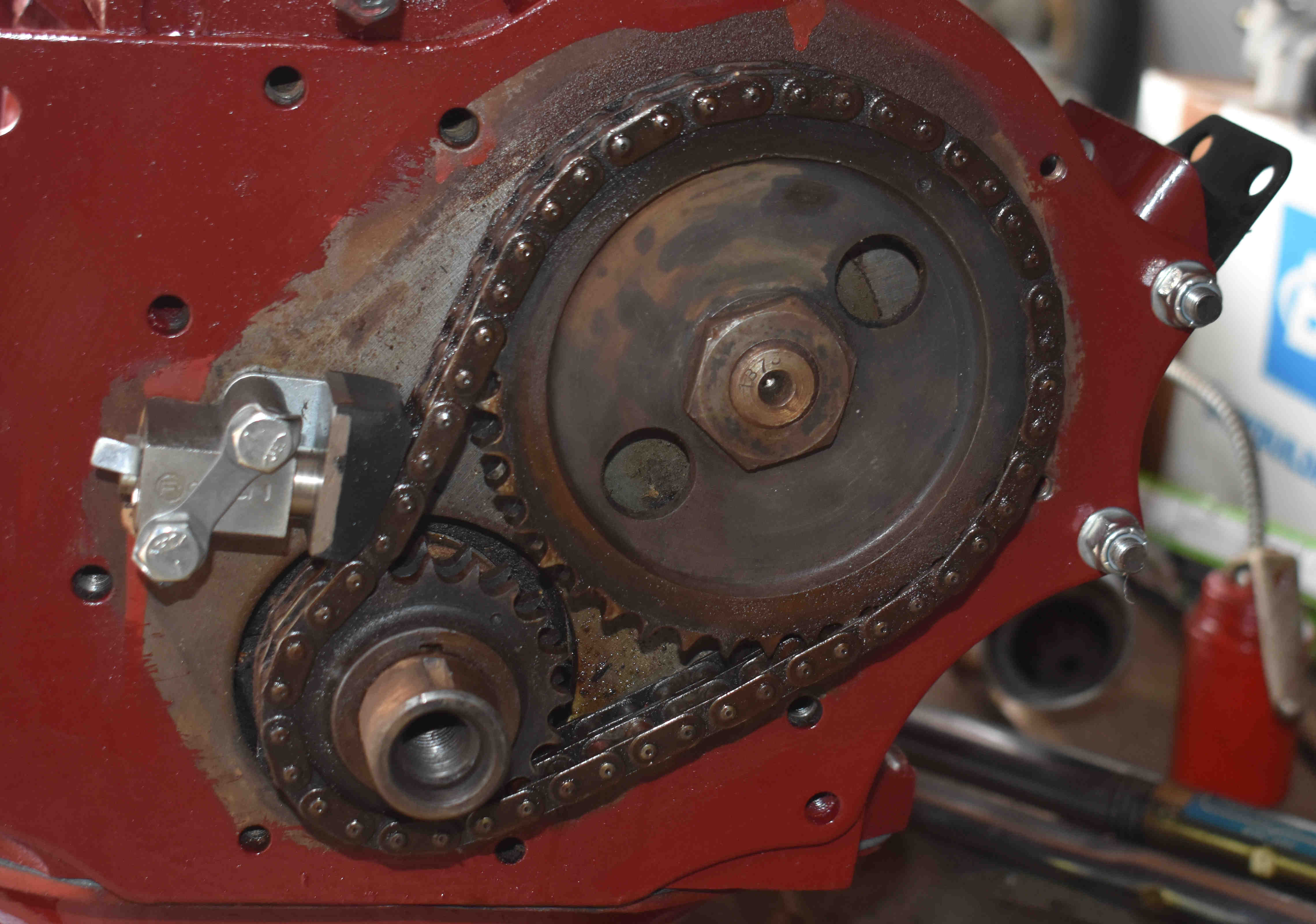

The timing chain tensioner was missing so a new one fitted and a good time to check the timing marks on the crank and camshaft align - they didn't, being one sprocket out. Whosoever rebuilt this engine did a good(ish) job but nothing can be taken for granted. Timing chain was removed then repositioned so that the marks align and good to go.

Click thumbnail

At some point the chain may have broken (does that happen?) as there was a mark with small hole on the inside to the timing cover - this was repaired with a quick weld and a grind. A new oil thrower (missing too) installed before timing cover replaced with new gasket and oil seal. I was unable to source a replacement crankshaft pulley but did find one from a Riley A30 1500 - same engine. It was very slightly larger but would probably do the job - unfortunately the extra diameter meant it totally obscured the timing marks so would make setting the timing much harder. I decided to tighten the rivets on the original pulley and use that.

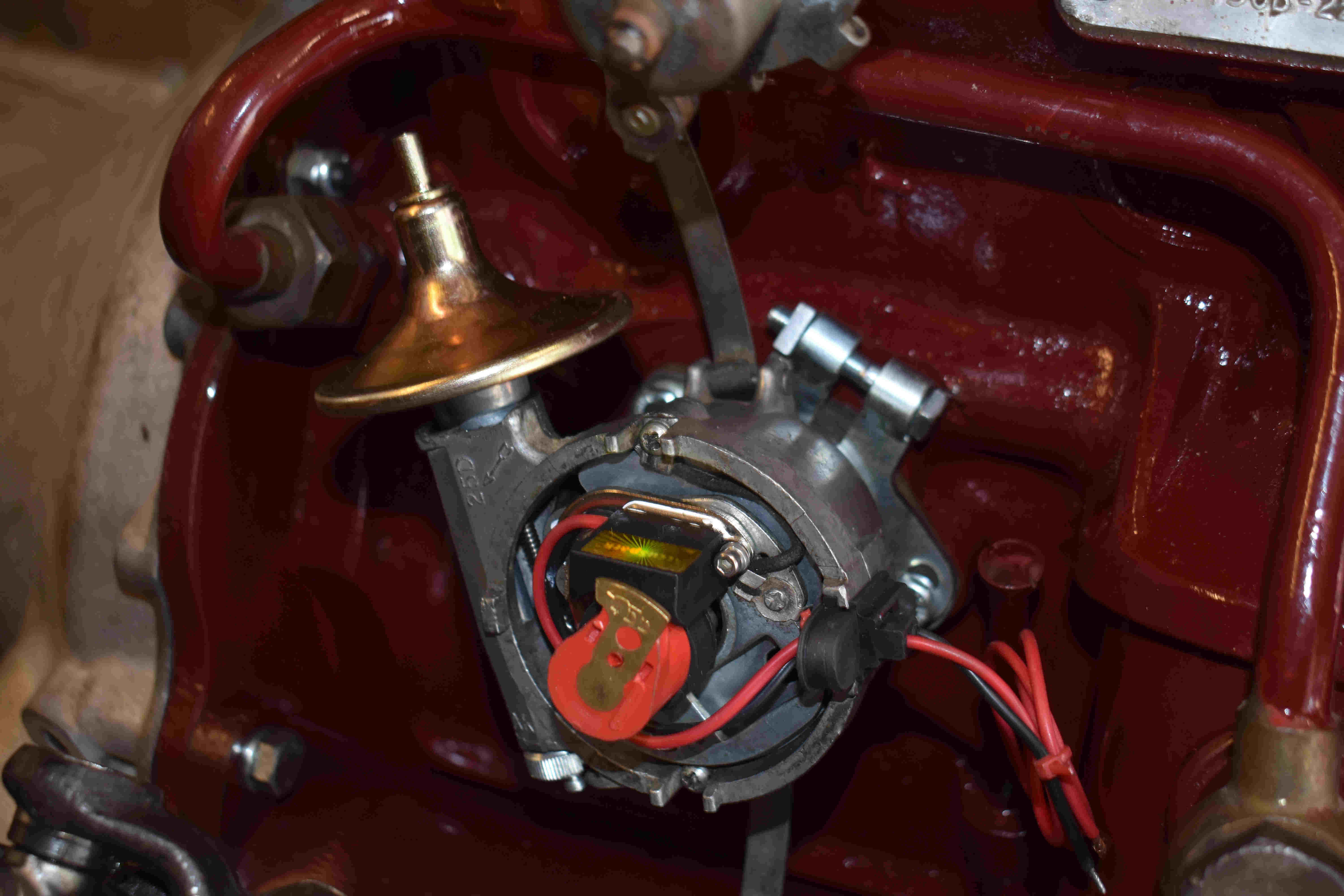

After the experience with the camshaft timing, another common pitfall is the distributor gear which can be fitted either correctly or 180 degrees out. Why should I be surprised it was not 180 degrees out, but completely missing, so a replacement procured and fitted.

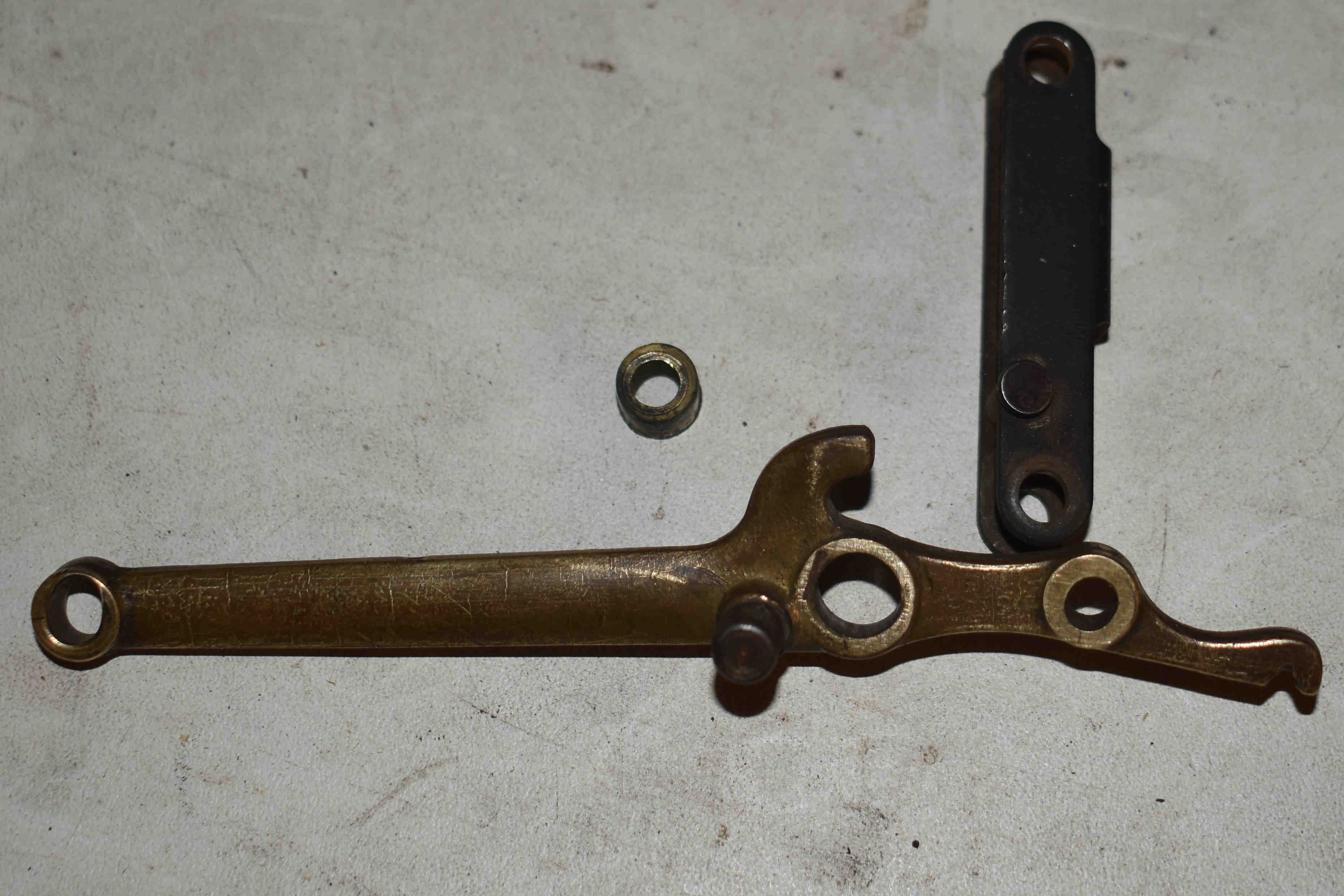

Next came the gearbox. The remote and gearlever were something else that was missing but I managed to buy a used part - once that was received I was happy that the gears could be selected and all the right bits would turn in the correct ratios. I'd no idea what state the clutch would be so was no surprise, when I split the bell housing from the engine, that the clutch was completely missing - not a problem as I was going to replace that anyway. The pin on the slave cylinder was very badly worn as someone had used a threaded bolt instead of a cotter pin, which acted as a saw on the pin. Again, no problem as that was replaced along with the complete slave cylinder.

It wasn't until I came to refit the flywheel that I read in the Workshop Manual "Mark the flywheel and crankshaft to ensure correct replacement." - too late. On the MG this is not much of a problem as the components are balanced prior to fitting but it seems a good idea. It also states "On some engines there is a 1/4 mark on the flywheel periphery and this must be in line with and on the same side as the first and fourth throws of the crankshaft flange". Many people have talked about this but they do not provide a photo so it took an age to find (see photo). With that back, the new Borg & Beck HK5110 (GCK257) clutch was fitted and the engine hoisted back into the chassis.

Click thumbnail

With the engine back in the chassis, attention could turn to the ancillaries. One of the nods to the modern era was to replace the dynamo with an alternator, and replace the distributor points with an Accuspark electronic ignition (and new vacuum advance mechanism) - both these are possible with the polarity changed from +ve to -ve earth. The starter motor was beyond repair (someone had tried in the past and broken an internal strap) so a secondhand one was refurbished and fitted.

The carbs were rebuilt with Vitron seals replacing the cork ones, with help from Tom Bryant's excellent instruction. Here, he warns that the choke linkage is meant to be loose with an oversize hole to allow the revs to increase before the mixture is enriched - some believe this is a fault so reduce the hole with a bush, meaning the throttle link will not fit properly. Yes, I had those bushes which, once removed, allowed the throttle to operate as designed.

Originally the coil fitted to a bracket fixed to the dynamo (now no longer there) but the later models use a bracket fixed to the engine mount - one of these was fabricated from a template on the MGAguru site.

Click thumbnail

Now, all the important stuff was put together, and the side wiring harness installed alongside the battery cable (to a single 12v battery, negatively earthed), with a petrol can feeding the fuel pump. So, in theory, there's no reason why it shouldn't start or, at least, make the appropriate sounds trying to fire. What happened next wasn't completely what I expected to happen.

Unfortunately, I'd forgotten that the oil / water gauge wasn't installed (as previous owner had chopped the oil capillary tube off when removing it in the past) so oil was spurting out of the tube under pressure, all over me! It didn't dampen my joy at the engine starting first time after (probably) 40 years and a rebuild. When the cooling system is installed I can run it up to temperature and fine tune the timing, carbs and do a compression test.

Then it's on to the bodywork.